Every industry is trending digital, including excavation. If hydro excavation is your preferred method, augmenting your fleet with a digital control console will empower you to work with greater efficiency than ever. Vortex by Tornado Global Hydrovacs is an innovative tool that will give your hydrovacs and operators complete control at the job site. Learn more about Vortex and how you can use it to advance your hydro excavation fleet’s capabilities.

What Is Vortex?

Vortex is a digital control console that is mounted in our lineup of Tornado Global Hydrovacs. The console features a display screen and buttons that the operator can use to set and change water pressure, as well as monitor transfer case temperature, blower temperature, hydraulic temperature, engine power, and blower power. Your operator can establish preset water pressures for each job and engage them with the press of a button.

Key Features of the Vortex Control Console

The Vortex console includes a few features that make it one of the most powerful and versatile on the market. Use Vortex to access tools like:

- Color-coded buttons and on-screen display feedback.

- Proactive maintenance notifications.

- Traceable system logs that track performance across jobs.

- Business intelligence system integration.

- Extreme temperature adaptability from minus 40 to 140 degrees Fahrenheit.

- Over-current and power output management.

What Advantages Does Vortex Offer?

Vortex’s expansive capabilities present numerous advantages for your business, including:

- Reliability: Vortex features military-grade hardware that meets standards for shock and vibration resistance. Additionally, the console’s industrial-grade IP67 optically bonded display will withstand the harshest environments. You can trust Vortex to meet your company’s needs.

- Safety: Vortex’s features ensure operator safety while protecting the hydro excavation equipment. Intelligent interlock and active monitoring systems keep tabs on the equipment’s performance and notify the operator when something goes awry. Vortex will help you prevent operator injury and costly equipment damage.

- Versatility: Vortex’s capabilities extend beyond controlling hydro excavation equipment. This console is also a powerful business tool. Vortex allows the operator to establish job-specific presets to impress with an optimal workflow. Additionally, Vortex will gather insights your company can use to inform business initiatives.

Vortex Connects with Mobile Devices

Your fleet can accomplish more when operators have the flexibility to oversee the entire job site. Vortex is compatible with mobile devices to allow your staff to control and monitor equipment performance from any location. Tornado Global Hydrovacs designs Vortex with Wi-Fi connectivity to send information like system pressure data, camera feeds, and GPS coordinates to a database you can view and control from a smartphone or computer.

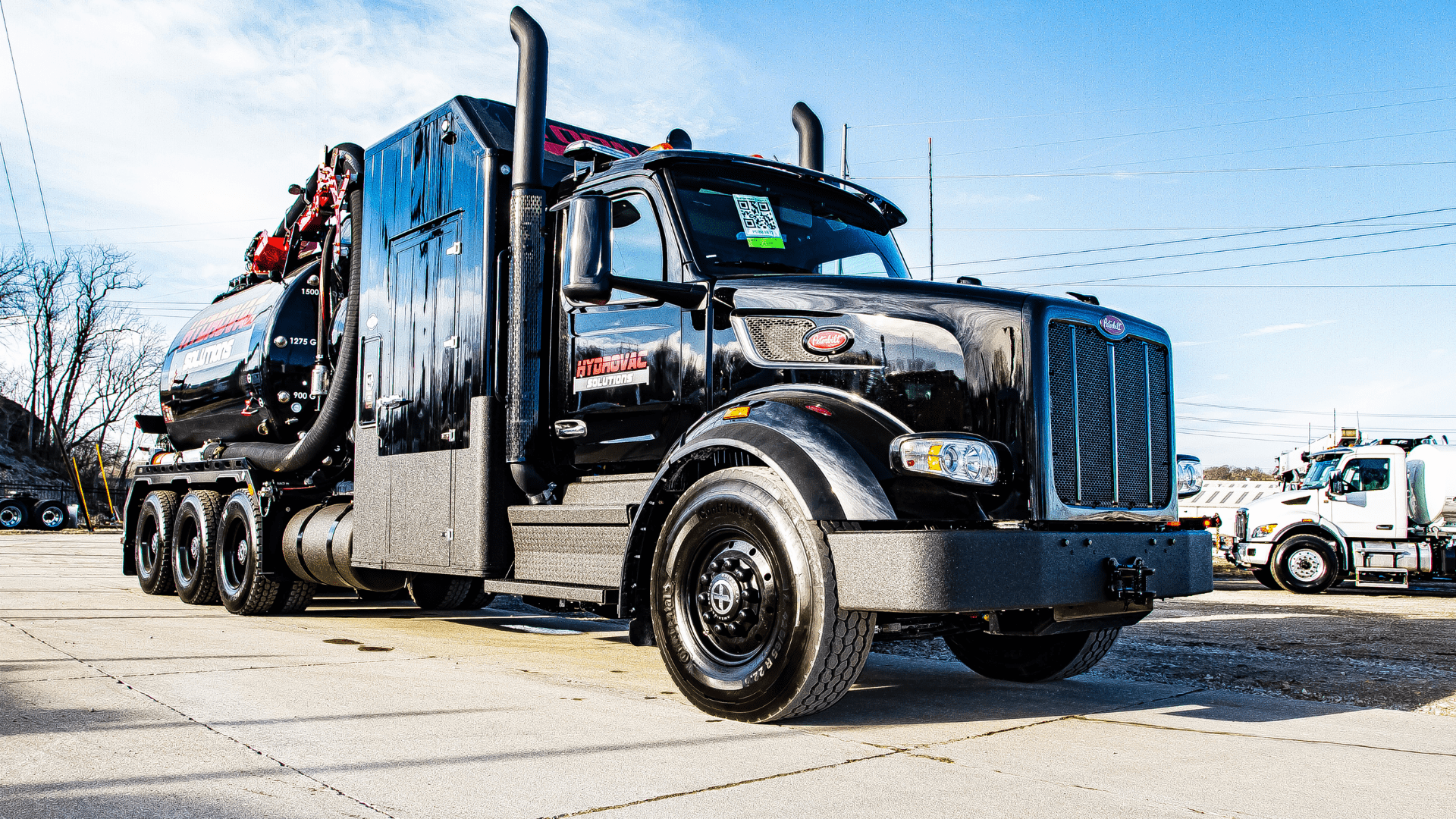

Purchase Tornado Global Hydrovacs Equipment From Custom Truck One Source

Hydro excavation is swiftly becoming the industry standard, and your company can maximize the benefits of its implementation by using an agile control system. You can purchase any of the Tornado Global Hydrovacs equipped with a Vortex control console through Custom Truck One Source. We are a single-source provider of heavy machinery like hydro excavation trucks. For more on the availability of hydro excavation equipment available through our locations nationwide, we encourage you to browse our inventory or contact us today.