What comes to mind when I say railroad? When asked, many might conjure up thoughts of freight trains, steam engines, frustrating waits at crossing gates, or the historic expansion to the old west. However, regarding the many rail professionals, who serve to maintain and construct our railway systems, we’d wager a few other things come to mind such as tie replacement, tie pick up and disposal, rail renewal, rail grinding, track surfacing, or today’s topic: vegetation control using a sprayer truck.

Weeds, Trees, & Railways

Invasive vegetation may merely exist as an eyesore for many of us. However, the same can’t be said for those MOW personnel tasked with maintaining the many rail systems that traverse our country’s landscape. When it comes to the railroads, these eyesores quickly turn into operational impediments and safety hazards. Railroads must adhere to strict regulations mandated by the FRA with regards to track clearance and grade crossings’ line of sight.

Such invasive vegetation is at its worst during the summer months of the year. Given the importance of meeting FRA regulations, railroads have in-depth programs and fleets to combat the advances of the dreaded weed and its counterparts. Multiple times a year, workers spray pre-emergent herbicides and other products used to prevent/neutralize invasive growth alongside and atop the trackbed to secure its infrastructure. Mother Nature can be resilient, but fortunately for all of us, the men and women who maintain our railway systems are, too.

Combating the Mean Green: The CTOS Sprayer Truck

As a consistent innovator of specialized hi-rail vehicles, one Shortline Railroad came to us in need of a unit that was more than the average sprayer truck. Asking ourselves “What are a few things a MOW crew must take into consideration when working a job?”, effectiveness, deadlines and versatility came to mind.

With these considerations, we took the job and decided to streamline the pre-existing notion of a spray-truck. Custom Truck One Source (CTOS) is proud to present our recent addition to the vegetation marketplace.

Just how we like things, the sprayer truck is a practical, streamlined, and adaptive system. Comprised of an F750 Extended Cab, a flatbed body, DMF Rail Gear, a specialized spray system, and a touchscreen control panel, this truck proves a reliable and expedient solution for many a MOW crew’s vegetation maintenance needs.

Sprayer Truck Features:

- 1000 Gallon Elliptical Tank

- Frame Sprayer Kit W/ Fork Pockets

- Dual Duty Design

- Raven 4 Injection System

- Dash Mounted Touchscreen Control Panel

- Hypro Spray Gun – 12V Hose Reel W/ Guide

- 300 FT of ½” Hose

- Honda GX 160 Hypro Pump

- 30 FT Collapsible Sprayer Boom

- Adjustable Boom Lengths & Nozzle Flows

Spray Boom

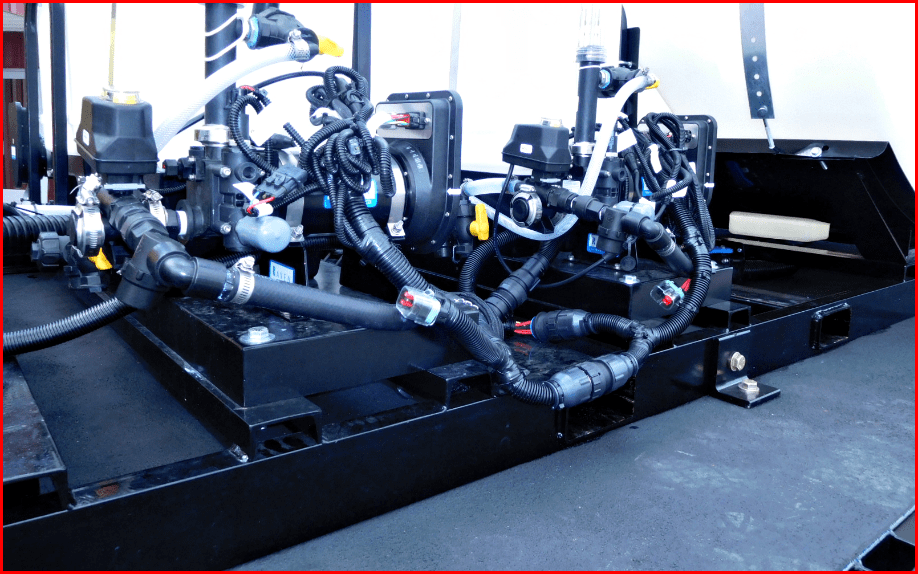

The sprayer kit utilizes Raven 4’s quad injection system. With dedicated product reservoirs and variable flow controls, the task of meeting the optimum water-to-product ratio is simplified. Once mixed within the dedicated reservoirs, strategically positioned spray nozzles dispense the product across the spray boom.

Depending on the boom’s configuration, the Sprayer Truck’s spray span may reach either 22 ft or 30 ft in length. Additionally, the Sprayer Truck’s boom may articulate via spring-loaded pivot points when meeting obstructions. The spray-boom’s sections may shift in either direction, smoothly retracting back into the proper position as the obstacle is passed. With a day’s work complete, both booms retract and fold into an upright position. The adaptability of the boom provides the operator both the ability to refine spraying patterns and some much-needed peace of mind.

Spray Gun

The Sprayer Truck also comes equipped with a Hypro Spray Gun. With 300 ft of hose, the operator can efficiently address clusters of vegetation outside the reach of the spray boom. The ½” hose retracts, via push button control, back onto its reel. The reel is conveniently located within the compartment below the spray gun’s dedicated tank.

Control Console

With simplicity in mind, the sprayer system operates via a touchscreen console. Situated inside the cab, within reach of the operator, the console controls all sprayer functions and provides a wide range of customizable features. One such feature allows the operator to save injector flow rates for future use. Each injector is allotted three unique flow rates, providing a myriad of presets to be utilized during future jobs.

Versatility

Finally, the CTOS Sprayer Truck is very multi-functional. Say you’re in a pinch. You have a situation that requires a hi-rail truck, but find the rest of your fleet allocated elsewhere. To pull an asset from its current job will put you behind schedule. To wait for one to free up will do the same. Well, no worries! With ease, an operator may convert the CTOS Sprayer Truck into a basic Hi-Rail flatbed. When initially approaching the bid, we did so with the intentions of making The Sprayer Truck a dedicated vegetation control vehicle; but as we ruminated on the project, we asked ourselves “Why make something dedicated when you don’t have to?”

Instead of welding the sprayer kit’s frame to the flatbed, we chose to make it a bolt-down attachment on a stripped-down version of our Spec 538T series. Engineered with removal in mind, fork pockets line the kit frame’s side channels. Upon removing the frame’s fasteners, the spray system may be lifted via forklift and stored somewhere safe, thus freeing the vehicle up for use as a Hi-Rail Flatbed.

It’s All in Our Name

We feel this Sprayer Truck is a testament to the customer-care provided by our sales staff, the ingenuity of our engineers and operations staff, and the execution of our mechanics.

Our customer shared with us that had they not received this truck when they did, they would have been forced to hire a contractor at a cost equal to that of the truck. In its first season the truck has paid for itself. When our products save our customers time and money, driving production forward, we may say that we’ve served them well.

We all have unique obstacles laid before us in our journeys. Sometimes the only way to overcome a unique obstacle is to employ a unique solution. If you find yourself in need of something that requires a custom touch, we’d ask that you keep us in mind because as we’ve said before… it’s all in our name: Custom Truck One Source.