Looking up at high-rise buildings, people often wonder how construction workers get large and heavy pieces of building material from ground level to the higher floors. It seems impossible that elevators could carry everything, or that workers could haul heavy material up winding staircases without damages or injuries.

Actually, materials of significant size and weight can’t be transported to higher stories from the inside. They instead must be hoisted up to the higher stories of the building from the outside. This is where wallboard loaders (or drywall loaders, as they are also called) come in.

When lifting solid pieces of material, like drywall (panels of gypsum plaster used to create walls and ceilings), a truck-mounted crane is the safest and most efficient solution to get products off the ground and delivered directly to the floor on which they will be used.

But what exactly is a wallboard loader?

Essentially, it is a truck with a crane that is similar to a knuckleboom. But, unlike a knuckleboom, this crane is designed to only bend in the middle (not a figure four configuration), and it stows unfolded on a boom rest.

Primarily used to unload drywall, the cranes can also be used in various other applications, such as hoisting roofing, steel studs, and palletized material (brick, wallboard, glass, etc.). They are compact in design with a low weight, so they offer the advantages of increased payload, fewer delivery runs, and a smaller workforce at the jobsite. We spoke to Dave Taff, Vice President of building materials at Custom Truck One Source, the leading supplier of heavy equipment in North America, to go over some common questions buyers have about drywall/wallboard loaders.

Excerpts from the interview:

What is the difference between a drywall loader and a drywall lift?

A lot of people think they are the same thing, but they are not. A drywall lift raises a drywall panel to a particular position for installation without requiring any assistance. A loader, on the other hand, lifts entire pallets of drywall to deliver them to the floors of buildings where they will be used.

Are there different types of drywall loaders?

They’re all the same type of equipment, really, but they are classified by the reach and capacity that they have. You start off with a 4-story crane (which will lift drywall up to four stories of a building). Then you have a 6-story, an 8-story, 9-story and a 10-story. There are also a few variations of these five.

Additionally, remember that a crane with a certain reach can still service stories lower than its maximum grade. For example, a 6-story crane can service the fifth floor of a building as well.

Tips on how to choose the right drywall loader?

It depends on what the end-user wants to do with the loader. For example, if a buyer is primarily working in the residential sector and wants to get on and off of a jobsite quickly, he should pick a 4-story model. If he is going to do a mix of commercial and residential, then he should choose a 6-story model. If he is primarily commercial, then he’ll choose somewhere between an 6-story and a 10-story model.

What types of companies typically use drywall loaders?

Primarily, with all the consolidation going on throughout the industry, it is going to be drywall suppliers, such as GMS (Gypsum Management & Supply Inc), L&W Supply, and Foundation Building Materials. They purchase drywall from various manufacturers, supply the material to contractors at commercial/residential jobsites, and unload it using drywall cranes. There are also independent drywall suppliers, such as Home Depot, Lowes, and independent lumberyards.

Today, the jobsites where wallboard cranes are used are probably 60% residential and 40% commercial. But the ratio changes depending on the economy.

Which category of drywall loaders is more popular than others?

The market has trended towards 6-story loaders, and now it’s trending towards the 9-story and 10-story. The latter is mostly for the commercial industry while the residential sector purchases 4-story and 6-story units.

Service is the key differentiator in the drywall loader market, and service is our biggest advantage. We are able to source parts and handle any other needs of our customers very quickly. After all, companies that use drywall loaders need their trucks to be up and running at all times in order to make money.

IMT (Iowa Mold Tooling Company) & Fassi

Drywall loaders from this company have become staples in the construction industry. They’re ideal for handling any stacked or palletized material, providing excellent lift capacity, impressive reach, precise maneuverability, and exceptional operator visibility even in tight places.

We carry the following drywall loaders by IMT:

• Maximum horizontal reach of 42’

• Maximum lifting capacity of up to 5,825 lbs

• Lifting height of up to 54’ 3”

• Optional, fully proportional radio remote control for increased productivity

• Maximum horizontal reach of up to 62′

• 420-degree rack and pinion

• Maximum lifting capacity of up to 5,700 lbs

• Height reach of up to 75′ 6″

• Maximum horizontal reach of up to 82' 10"

• Radio remote with InfoCenter

• 420-degree turntable bearing powered by dual hydraulic motors

• Heavy-duty gearbox equipped with a heat-treated pinion

Over 90% of a Fassi crane is manufactured in one of the Fassi factories, all of which are located in Italy. In order to guarantee the highest levels of product quality, the Fassi Industrial group is set up to cover the entire manufacturing cycle: from metal sheeting to the finished crane. Their products are imported to the United States via Baltimore, Maryland.

We carry the following drywall loaders by Fassi:

1) F245SE.04 Loader

• Lifting capacity of up to 252,172 lbs

• Vertical reach up to 72'

• Rotation arc 470°

2) F280SE.22 Loader

• Lifting capacity of up to 186,732 lbs

• Maximum outreach of up to 50’ 3”

• Rotation 420° with rack and pinion

• Overall dimensions: l 3' 2", w 8' 2", h 9' 2"

2) F330SE.24 Loader

• Lifting capacity of up to 168,485 lbs

• Maximum outreach of up to 58’ 9”

• Overall dimensions: l 3' 2", w 8' 2", h 9' 6"

• Rotation 420° with rack and pinion

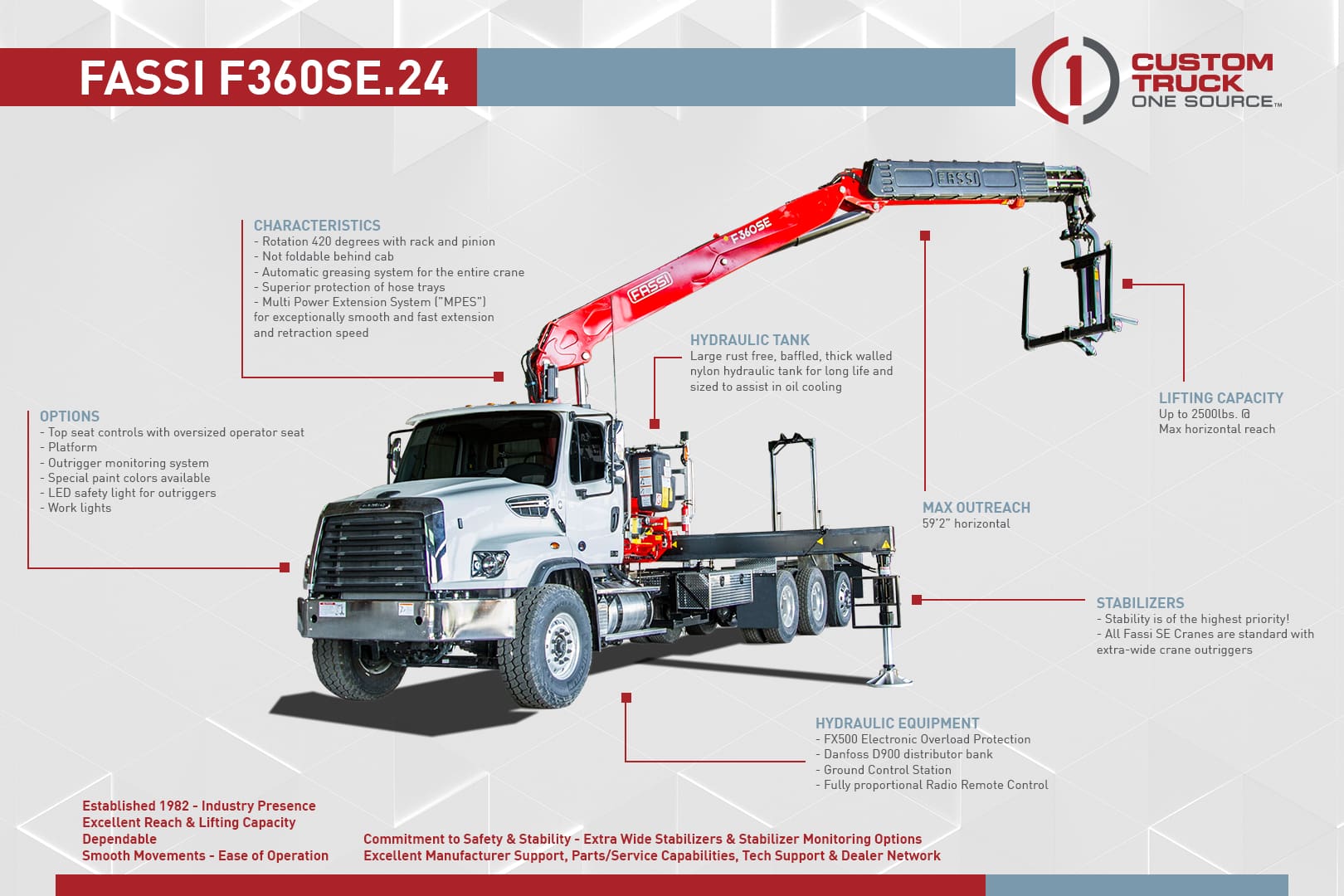

3) F360SE.24 Loader

• Maximum lifting capacity of up to 215,768 lbs

• Maximum outreach of up to 59’ 2”

• Overall dimensions: l 3' 2", w 8' 2", h 9' 6"

• Rotation 420° with rack and pinion

4) F390SE.24 Loader

• Maximum lifting capacity of up to 270,868 lbs

• Maximum outreach of up to 78’ 11”

• Overall dimensions: l 3' 4", w 8' 2", h 9' 4"

• Rotation 430° with rack and pinion

5) F600SE.44 Loader

• Tallest and most functional wallboard crane on the market.

• Computer graphics for the first time to present one of its cranes

• Available with exclusive Fassi Internet of Cranes® “IoC” system, which allows operators to count on the web

Custom Truck One Source has you covered!

We’re America’s first true single-source provider of specialized truck and heavy equipment solutions and we’re standing by to help you!

Call us at 844-282-1838 or email us at mailto:[email protected].